Heat transfer & PCM

Thermal energy storage is a key technology for energy conservation since many energy sources are intermittent in nature. Latent heat storage is considered one of the most efficient ways of storing thermal energy because, unlike sensible heat storage, it provides a high-energy storage density with a small temperature swing. Fixed and fluidized beds may be feasible technologies when the storing materials may be encapsulated in cans, spheres or microencapsulated in highly porous structures with protecting envelopes.

One of the research topics of the ISE group is to study the behavior of a bed with granular phase change materials (PCMs) as a thermal storage system. Both, experimental and numerical studies are performed, for instance:

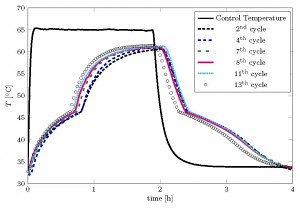

Temperature profiles for different cycles under the same experimental conditions for the PCM in a fluidized bed

Charging and discharging experiments and models for the transient response of the bed for fixed and fluidized bed configurations. Izquierdo-Barrientos M.A., Sobrino C., Almendros-Ibáñez, J.A. (2015) “ Thermal energy storage in a fluidized bed of PCM ”, Chemical Engineering Journal, 230, 2013, 573-583.

Evolution of the heat transfer coefficient, hw, in a fluidized bed for different flow rates for PCM.

Study of the heat transfer coefficient between the bed of PCM and an immersed surface. Izquierdo-Barrientos M.A., Sobrino C., Almendros-Ibáñez, J.A. (2015) “ Experimental heat transfer coefficients between a surface and fixed and fluidized beds with PCM ”, Applied Thermal Engineering, 78, 373-379.

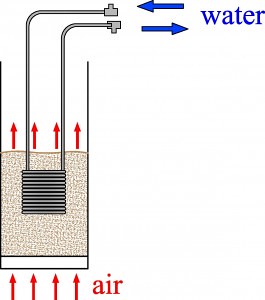

Experimental study of a fluidized bed with granular PCM with an internal heat exchanger

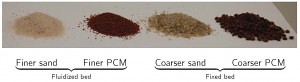

The experimental studies are conducted in a cylindrical bed filled with granular PCM and with air as the working fluid. The bed has an internal diameter of 200 mm. The granular PCMs used consist of paraffin, which is the material that changes its phase, bounded within a secondary supporting structure of SiO2. The material is commercialized by Rubitherm®. The performance of the PCM is compared to sand, a well-known storage material.